All You Need to Know About PUR Hot Melt Adhesive

If you're in the manufacturing or construction industry, you may have come across the term "PUR hot melt adhesive." In this comprehensive guide, we will delve into the world of PUR hot melt adhesive, exploring its uses, benefits, and application techniques. Whether you're a professional or a DIY enthusiast, understanding the power of PUR hot melt adhesive will revolutionize the way you approach bonding projects.

What is PUR Hot Melt Adhesive?

PUR adhesive, short for polyurethane reactive, hot melt adhesive is a type of adhesive that provides superior bonding strength and durability. It is commonly used in industries such as woodworking, packaging, automotive, construction, and textiles. PUR hot melt adhesive is thermoplastic, meaning it can be melted and solidified repeatedly without compromising its adhesive properties.

The Benefits of PUR Hot Melt Adhesive

Using PUR hot melt adhesive offers a wide range of benefits that make it a popular choice among professionals. Let's explore some of the advantages that make PUR hot melt adhesive stand out:

1. Exceptional Bonding Strength

PUR hot melt adhesive creates incredibly strong bonds, even on challenging surfaces and materials. It forms a permanent bond that can withstand varying temperatures, moisture, and other environmental factors. This exceptional bonding strength ensures the longevity and reliability of your projects.

2. Versatility

PUR hot melt adhesive is compatible with a wide range of materials, including wood, metal, plastics, textiles, foam, and more. This versatility makes it a go-to adhesive for various applications, such as furniture assembly, edge banding, laminating, product packaging, and even automotive interior installations.

3. Heat and Moisture Resistance

Unlike some traditional adhesives, PUR hot melt adhesive exhibits excellent resistance to heat and moisture. This makes it suitable for applications that require durability in challenging environments, such as outdoor furniture or products exposed to high humidity.

4. Flexibility and Impact Resistance

PUR hot melt adhesive maintains its flexibility even after curing, allowing it to withstand movements and vibrations without compromising the bond. It also provides excellent impact resistance, making it ideal for applications that require durability under stress or heavy loads.

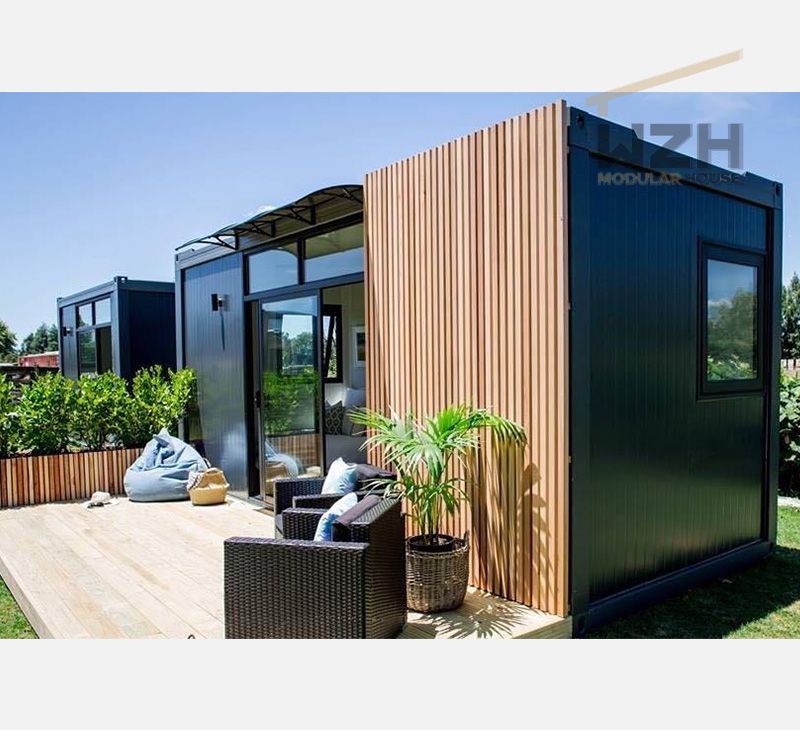

Additional reading:What are the pros and cons of living in a shipping container house?

Construction and Geotechnical Applications: Top Hammer Drill Rigs in Action

What Are the Key Functions of Different Signage Types?

Advantages of Hot Dipped Galvanized Water Tanks for Rural Water Storage

How to Improve Foundry Efficiency with SIC Ceramic Foam Filters

What types of designs and subjects can marble statues depict?

The Superiority of HDPE Pipes in Potable Water Systems

5. Wide Operating Temperature Range

PUR hot melt adhesive can be applied and cured over a wide temperature range. This flexibility enables its use in various manufacturing processes, accommodating different material requirements and assembly conditions.

How to Apply PUR Hot Melt Adhesive

To ensure optimal results when using PUR hot melt adhesive, follow these application techniques:

1. Surface Preparation

Before applying PUR hot melt adhesive, ensure that the surfaces to be bonded are clean, dry, and free from dust, grease, or other contaminants. Proper surface preparation promotes better adhesion and maximizes the bonding strength.

2. Melting and Application

PUR hot melt adhesive is typically applied using a hot melt applicator or glue gun. The adhesive is heated until it reaches the appropriate melting temperature and then applied to the desired surfaces. Use the appropriate nozzle or dispenser tip to control the adhesive flow and achieve the desired bead size.

3. Assembly and Curing

After applying the adhesive, quickly assemble the parts while the adhesive is still molten. Apply sufficient pressure to ensure proper contact and bond formation. The adhesive will begin to cool and cure, achieving its full bonding strength over time.

4. Cleanup and Maintenance

To maintain the efficiency and lifespan of your equipment, it's crucial to clean the glue gun or applicator regularly. Follow the manufacturer's instructions for proper maintenance and use cleaning agents designed specifically for PUR hot melt adhesive.

More details please visit: www.raywincoating.com

What Are the Advantages of GFS Tanks?

The Role of Geogrid in Soil Stabilization and Reinforcement

What are the maintenance requirements for a shipping container home?

Why is granite good for monuments?

Advantages of Anaerobic Digester Tanks

Where are Hot-Dip Galvanized Steel W Beam Guardrails Used?

What are the properties of H20 beams?

Previous: How Does the Quality and Durability of Granite Headstones Compare to Other Materials?

Next: Swimming Pool Heat Pumps: Efficient Heating Solutions for Pools

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0