What factors should businesses consider when choosing the right IML packaging solution for their specific products?

In-Mold Labeling (IML) is a popular packaging solution that combines the label and container manufacturing processes into one step. When businesses are considering IML for their products, several crucial factors should be taken into account to ensure the most suitable and effective packaging solution. Here are the key considerations:

1. Product and Packaging Compatibility: Ensure that the IML packaging solution is compatible with the specific product being packaged. Consider factors such as the product's size, shape, and weight, as well as any unique requirements for handling or storage. The packaging should protect and showcase the product appropriately.

2. Label Material and Design: Choose the right label material for your IML packaging. Labels can be made from different materials, including polypropylene (PP) and polyethylene (PE), each with distinct characteristics. The label design should effectively convey branding, product information, and any necessary regulatory details.

3. Printing and Graphics Quality: The printing quality and graphic representation on the IML label are critical for attracting consumers and promoting the product effectively. Choose a packaging solution that offers high-quality printing capabilities and vibrant graphics to enhance the overall appearance of the product.

4. Label Durability and Resistance: Consider the durability and resistance of the IML label to external factors such as moisture, heat, chemicals, and UV exposure. The label should maintain its integrity and legibility throughout the product's shelf life and during transportation.

5. Production Efficiency and Speed: Evaluate the production efficiency and speed of the IML packaging solution. Efficient processes can reduce manufacturing costs and increase output, ensuring a steady supply of products to meet market demand.

6. Regulatory Compliance and Safety: Ensure that the IML packaging solution complies with relevant industry standards and regulations. This is especially important for products that have specific labeling requirements, such as nutritional information, safety warnings, or recycling symbols.

Additional reading:Which Non Woven Bag Material is Best?

Revolutionize Your Brand with Custom Sticker Sheets!" - Which design stands out from the rest?

Ultimate Guide to Non Woven Bag Printing

New meaning for custom vinyl sticker for commercial signage: Interactive QR code stickers for improving engagement?

Jumbo Concrete Bag: The Perfect Solution for Large-Scale Construction Projects

The Benefits of Using PE Film

Exploring the World of DTF Ink: A Comprehensive Guide

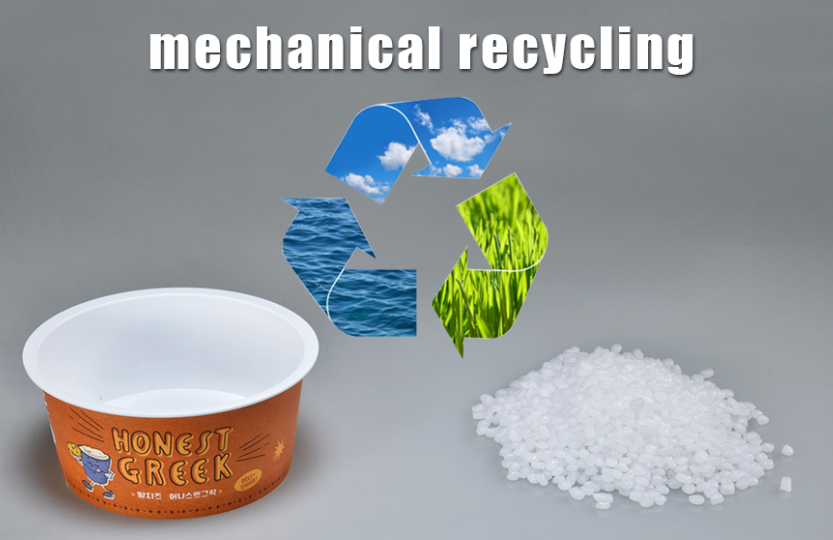

7. Sustainability and Environmental Impact: Consider the environmental impact of the IML packaging solution. Opt for materials that are recyclable or made from sustainable sources to align with eco-friendly initiatives and consumer preferences.

8. Supplier Expertise and Support: Choose a reliable and experienced IML packaging supplier. Look for a partner who can provide technical expertise, customization options, and responsive customer support to address any specific needs or challenges.

9. Branding and Market Appeal: The IML packaging should align with your brand identity and target market. Eye-catching and well-designed packaging can enhance brand recognition and appeal to consumers, increasing the product's marketability.

10. Cost-effectiveness: While considering all the above factors, also assess the overall cost-effectiveness of the IML packaging solution. It should provide a balance between quality, functionality, and budget considerations.

Conclusion: Selecting the right IML packaging solution is a crucial decision for businesses as it impacts product presentation, protection, and consumer perception. By carefully evaluating factors such as product compatibility, label materials and design, printing quality, durability, regulatory compliance, sustainability, supplier expertise, and cost-effectiveness, businesses can make an informed choice that ensures their products are well-packaged, visually appealing, and ready to stand out in the competitive market.

Applications of Bromobutyl Rubber Stopper

The Role of CNG Gas Cylinders

Pet Foods Packaging: Ensuring Quality and Convenience for Your Furry Friends

The Benefits of Push Pull Water Bottle Caps

Exploring the Applications and Advantages of PE Aluminum Profile Protective Film

The Essential Guide to LPG Cylinder Safety: Tips and Best Practices

What Size Tarp for Camping?

Previous: Advantages and Applications of Seamless Steel Cylinder

Next: Which industries benefit the most from using shrink film for packaging and product protection?

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0