Electric Heat Tracing Design: Ensuring Optimal Efficiency and Performance

In the realm of modern engineering, electric heat tracing has emerged as a crucial technology that facilitates the maintenance of desired temperatures in pipelines, vessels, and other industrial equipment. The effective design and implementation of electric heat tracing systems are paramount to ensure optimal efficiency, prevent freezing, and maintain the integrity of critical processes. In this comprehensive guide, we will delve into the intricacies of electric heat tracing design, covering essential concepts, methodologies, and considerations that are essential for engineering professionals and decision-makers alike.

Understanding Electric Heat Tracing

Electric heat tracing is a method used to compensate for heat losses from pipelines and equipment by utilizing electrical heating cables. These cables are specifically designed to generate heat and distribute it evenly along the length of the system, preventing freezing, maintaining viscosity, and safeguarding the integrity of materials being transported.

Key Components of Electric Heat Tracing

To design an efficient electric heat tracing system, several key components come into play:

1. Heating Cables

The heart of the system lies in the heating cables. There are two main types: self-regulating and constant wattage. Self-regulating cables automatically adjust their power output based on the ambient temperature, providing energy savings and preventing overheating. On the other hand, constant wattage cables maintain a consistent heat output irrespective of the temperature.

2. Control and Monitoring Systems

Efficient control systems are essential to manage the heat tracing system effectively. They ensure that the system operates optimally, preventing excessive energy consumption. Advanced monitoring systems enable real-time temperature tracking and issue alerts in case of anomalies, allowing swift corrective action.

3. Insulation

Proper insulation is vital to enhance the heat tracing system's efficiency. Insulation minimizes heat loss to the surroundings, ensuring that the heat generated is directed toward maintaining the desired temperature within the system.

4. Power Distribution

Designing a well-structured power distribution system is crucial. It ensures that the heating cables receive the required power without causing overload or voltage drops. Properly sized circuit breakers and transformers are integral to this aspect.

Design Methodology

The process of designing an effective electric heat tracing system involves several systematic steps:

1. Heat Loss Analysis

Before embarking on the design, a thorough heat loss analysis must be conducted. This involves calculating the heat loss from the system to determine the appropriate heat tracing cable type, length, and power output.

Best message queue for cloud-native apps

Pressure Testing Pipe with Nitrogen

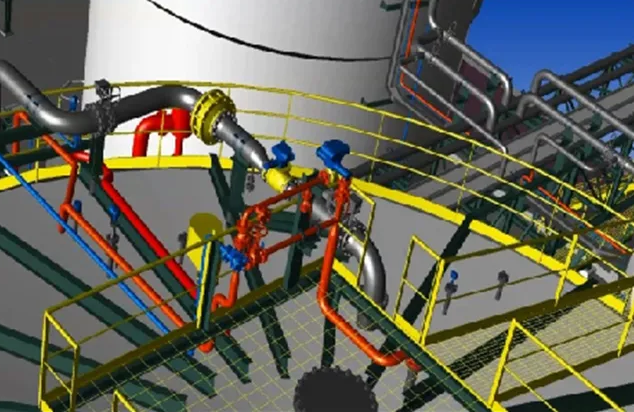

2. Cable Layout and Placement

Based on the heat loss analysis, the cable layout and placement are determined. Critical areas prone to heat loss or freezing are identified, and the cables are strategically placed to ensure even heat distribution.

3. Temperature Control

Choosing the right control system is essential for maintaining the desired temperature. Proper temperature sensors are placed at key points along the system to ensure accurate monitoring and regulation.

4. Insulation Selection

Selecting the appropriate insulation material is paramount. Factors such as temperature range, exposure to corrosive substances, and insulation thickness must be considered to prevent heat loss and ensure safety.

Considerations for Optimal Design

To achieve a superior electric heat tracing design that outperforms the competition, consider the following aspects:

1. System Flexibility

An efficient design should accommodate changes in the system's requirements without extensive modifications. This flexibility ensures adaptability to evolving industrial needs.

2. Energy Efficiency

Opt for self-regulating heating cables wherever applicable. These cables adjust their heat output in response to ambient conditions, leading to energy savings and reduced operational costs.

3. Longevity and Reliability

Invest in high-quality components and cables with proven reliability. This ensures that the heat tracing system operates seamlessly for an extended period, minimizing downtime and maintenance costs.

4. Compliance and Safety

Adhere to industry standards and guidelines for electrical systems and safety protocols. A well-designed system not only performs efficiently but also ensures the safety of personnel and the environment.

In Conclusion

Electric heat tracing design is a critical aspect of modern industrial operations that demand precise temperature control. By understanding the key components, design methodology, and considerations for optimal efficiency, engineering professionals can craft superior heat tracing systems that enhance operational reliability, minimize downtime, and contribute to overall process integrity.

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0