Precision Redefined: Exploring the World of CNC Cylindrical Grinding Machines

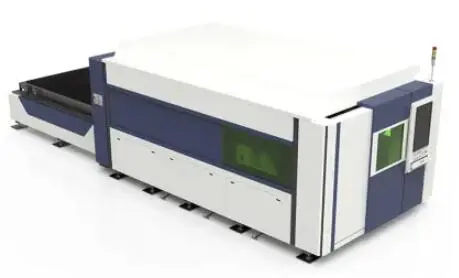

In the realm of precision machining, CNC cylindrical grinding machines have emerged as indispensable tools for achieving unparalleled accuracy and surface finish. These advanced machines utilize computer numerical control (CNC) technology to automate the grinding process, allowing for precise and efficient production of cylindrical components. In this article, we will delve into the world of CNC cylindrical grinding machines, exploring their features, benefits, and the industries they revolutionize.

Unmatched Precision and Versatility

CNC cylindrical grinding machines are renowned for their ability to deliver exceptional precision. These machines employ computer-controlled movements to grind cylindrical workpieces with remarkable accuracy, achieving tight tolerances and superior surface finishes. The CNC technology ensures consistency and repeatability, allowing manufacturers to produce high-quality components to exact specifications.

Moreover, CNC cylindrical grinding machines offer versatility in terms of the range of workpieces they can accommodate. They can handle a variety of cylindrical shapes and sizes, from small parts to large and complex components. This adaptability makes them ideal for applications in industries such as aerospace, automotive, medical, and tooling, where precision is paramount.

Efficient and Cost-Effective Production

CNC cylindrical grinding machine significantly improve production efficiency and reduce costs. The automation provided by CNC technology eliminates the need for manual intervention, resulting in faster cycle times and increased productivity. With the ability to perform multiple operations in a single setup, these machines optimize machining time and minimize idle periods, maximizing the utilization of resources.

Additionally, CNC cylindrical grinding machines reduce material waste and rework. The precise control over the grinding process ensures minimal material removal, minimizing scrap and improving overall material utilization. This, coupled with the ability to program complex grinding paths and geometries, reduces the need for additional operations and setups, further enhancing efficiency and cost-effectiveness.

Additional reading:The Role of Flying Shear Quick Straightening and Cutter in Steel Mills

How To Maintain Scissor Lifts And Boom Lifts?

Electromagnetic Induction Water Heater Theory and Advantage

Exploring Different Maize Flour Milling Machine Types and Their Applications

Understanding the Process of EPS Shape Molding

What does a CNC lathe produce?

Are Carton Sealing Machines the Ultimate Packaging Solution?

Superior Surface Finish and Quality

Achieving a high-quality surface finish is crucial in many industries. CNC cylindrical grinding machines excel in this regard, delivering exceptional surface finishes that meet the strictest requirements. The CNC control allows for precise control over grinding parameters such as feed rates, spindle speeds, and depth of cut, resulting in consistent and uniform surface finishes across multiple workpieces.

Furthermore, CNC cylindrical grinding machines enable manufacturers to maintain tight tolerances, ensuring the dimensional accuracy of the finished components. The ability to control grinding forces and minimize thermal deformation guarantees consistent part sizes and geometries, even during long production runs. This level of accuracy and quality contributes to the overall reliability and performance of the final products.

Enhanced Operator Safety and Comfort

Safety is of utmost importance in any manufacturing environment, and CNC cylindrical grinding machines incorporate advanced safety features to protect operators. These machines are equipped with safety interlocks, emergency stop buttons, and protective enclosures to prevent accidents and ensure operator well-being. The CNC automation reduces the need for manual handling of the workpieces, further enhancing operator safety.

Moreover, CNC cylindrical grinding machines are designed with operator comfort in mind. They feature ergonomic controls and interfaces that are intuitive and user-friendly, minimizing operator fatigue and facilitating ease of use. The reduced physical strain on operators contributes to a safer and more efficient working environment.

Conclusion

CNC cylindrical grinding machines have revolutionized precision machining, offering unmatched precision, versatility, and efficiency. With their ability to achieve tight tolerances, superior surface finishes, and consistent quality, these machines have become indispensable in industries that demand precision components. The automation provided by CNC technology enhances productivity and reduces costs, while the safety features and operator comfort contribute to a safer working environment. As technology continues to advance, CNC cylindrical grinding machine will continue to shape the future of precision manufacturing, redefining the boundaries of what is possible.

Additional reading:What Are The Characteristics of Automatic Plastic Glove Machine?

What are the different types of dump trucks?

Ozone Generators vs Ionizers: Unveiling the Contrasts

What is the working principle of tube mill?

What are the cons of lost foam casting?

Which Impellers Are Best For Slurry Pump Applications?

How To Maintain The Welding Positioner?

Previous: SMT AGV Equipment: Revolutionizing Manufacturing Processes

Next: Enhancing Efficiency and Precision: The Power of Induction Heating Systems for Forging

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0