How to Choose the Right Electrical Flexible Conduit for Your Needs?

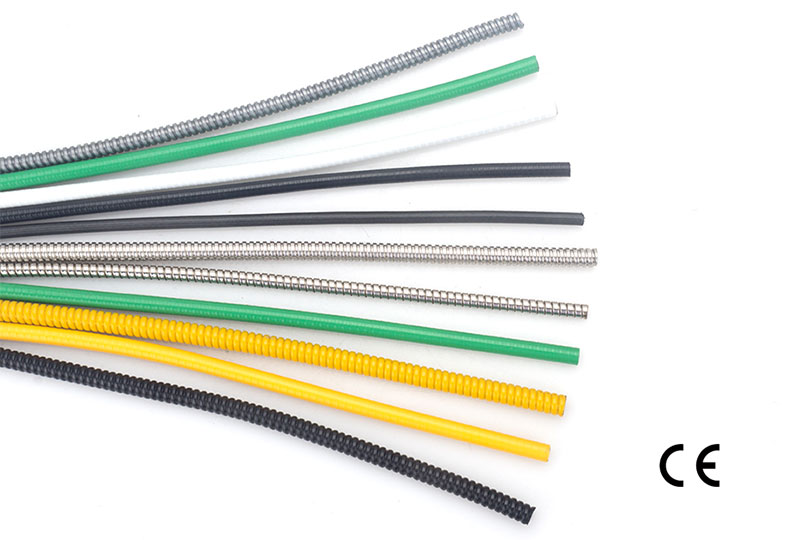

Before diving into the selection process, let's gain a clear understanding of what electrical conduits are and their importance in electrical systems. Electrical flexible conduits are protective tubes designed to encase and safeguard electrical wires, cables, and other conductors. They are commonly used in industrial, commercial, and residential settings to provide mechanical protection and prevent hazards.

Factors to Consider When Choosing Electrical Flexible Conduits

Selecting the right electrical flexible conduit involves evaluating several critical factors to ensure it aligns perfectly with your project requirements. Let's explore these factors in detail:

1. Environmental Conditions

Consider the environmental conditions where the conduit will be installed. If the installation is indoors, non-metallic conduits may suffice. However, for outdoor or harsh environments, metallic or liquidtight conduits become more appropriate.

2. Flexibility and Bend Radius

The flexibility and bend radius of the conduit are essential, especially when navigating tight spaces or corners during installation. Flexible conduits should allow easy bending without causing damage to the wires inside.

3. Temperature Rating

Check the temperature rating of the conduit to ensure it can withstand the highest and lowest temperatures it might be exposed to in its intended environment.

4. Corrosion Resistance

For outdoor or corrosive environments, corrosion-resistant conduits like stainless steel or certain non-metallic options are preferable to ensure longevity and performance.

5. Mechanical Strength

Consider the mechanical strength of the conduit, especially if it will be subject to physical stress or potential impact.

6. Size and Diameter

Ensure that the conduit's size and diameter can accommodate all the wires and cables that need protection. An undersized conduit may lead to overheating and reduced airflow.

7. UL Certifications

Look for conduits that are UL (Underwriters Laboratories) listed or certified. UL certifications ensure that the conduit meets safety and performance standards.

8. Installation Method

Different conduits may require specific installation methods. Consider whether the conduit needs to be glued, clamped, or threaded for installation.

Additional reading:Understanding the Distinction: J-Bolt vs. Anchor Bolt

Advantages and Applications of Metal Glazed Film Resistors

The Ultimate Guide to Portable Power Stations: Everything You Need to Know

Why is an LFP Battery a Reliable and Long-Lasting Energy Storage Solution for Portable Power Stations?

What Are the Benefits of Using an Electric Under Blanket for a Restful and Warm Night's Sleep?

Surface Mount Package Sizes

Gas Insulated Switchgear: Enhancing Electrical Grid Performance

9. Cost and Budget

While quality should never be compromised, it's essential to consider the conduit's cost and how it fits within your budget.

Steps to Choose the Right Electrical Flexible Conduit

Now that we have explored the crucial factors, let's go through a step-by-step process to select the ideal electrical flexible conduit for your specific needs:

Step 1: Assess Your Project Requirements

Understand the scope of your electrical project, including the environment, application, and the types of wires and cables involved.

Step 2: Identify Potential Hazards

Evaluate potential hazards such as moisture, chemicals, physical impact, or extreme temperatures that the conduit might encounter.

Step 3: Determine the Size and Diameter

Accurately measure the size and diameter of the wires and cables that will pass through the conduit. Ensure you have adequate space for all the conductors.

Step 4: Choose the Conduit Material

Based on your assessment, select the most suitable conduit material – metallic, non-metallic, or liquidtight – that meets your project requirements.

Step 5: Consider the Flexibility

Ensure the chosen conduit is flexible enough to bend and maneuver through the required spaces without compromising the wires inside.

Step 6: Check Certifications and Ratings

Verify that the conduit has the necessary certifications, such as UL listing, and ratings like temperature, flame resistance, and corrosion resistance.

Step 7: Compare Costs and Budget

Finally, compare the costs of the shortlisted conduits and align them with your budget constraints while prioritizing quality and safety.

Conclusion

Choosing the right electrical flexible conduit is a critical aspect of any electrical installation project. By considering the environmental conditions, flexibility, temperature rating, corrosion resistance, and other factors discussed in this guide, you can confidently select a conduit that meets your specific needs.

Remember, safety should always be the top priority, and investing in a high-quality conduit will ensure a long-lasting and reliable electrical system.

Additional reading:Exploring the Versatility and Benefits of Electrical Flexible Conduit

Factors to Consider when choose LCD Module

Advantages and Applications of Gas Insulated Switchgear

Advantages of SIP Trunking

Understanding ESD Protection: How PCB Consumables Prevent Static Damage

The Anatomy of Precision Instruments PCBA

SMT PCB Buffer vs. Conveyors: Which Is Better for Your Assembly Line?

Previous: Do String Lights need to be UL certified?

Next: What is the difference between welding cable and normal cable?

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0