Powering the Future: The Lithium Battery Module Assembly Line

Lithium-ion batteries have revolutionized the world of portable electronics and are increasingly being used in electric vehicles, energy storage systems, and renewable energy applications. The efficient and reliable production of lithium battery modules is critical to meet the growing demand for these advanced energy storage solutions. The lithium battery module assembly line plays a pivotal role in manufacturing high-quality battery modules. In this article, we will explore the significance of the lithium battery module assembly line and its role in powering the future.

Efficient and Automated Manufacturing

The lithium battery module assembly line is designed to streamline and automate the manufacturing process, ensuring efficient and consistent production of battery modules. Through a series of automated steps, including cell sorting, welding, stacking, and encapsulation, the assembly line enables a high-volume production capacity. The integration of advanced robotics, precision machinery, and intelligent control systems optimizes the manufacturing process, reduces human error, and enhances production efficiency.

Quality Control and Testing

Maintaining high-quality standards is crucial in lithium battery module production. The assembly line incorporates rigorous quality control measures to ensure that each battery module meets stringent specifications and safety requirements. Automated testing stations are integrated into the assembly line to conduct comprehensive performance and safety tests on each module. These tests include capacity measurements, electrical impedance analysis, temperature stability, and short circuit protection. Through these quality control measures, the assembly line ensures the production of reliable and safe battery modules.

Flexibility and Scalability

The Lithium battery module production offers flexibility and scalability to adapt to the evolving needs of the energy storage industry. It can accommodate different battery cell chemistries, sizes, and configurations, allowing for customization based on specific applications. The modular design of the assembly line enables easy reconfiguration and expansion, ensuring scalability to meet increasing market demands. This flexibility and scalability are vital in a rapidly evolving industry where new battery technologies and applications emerge frequently.

Additional reading:Harnessing the Power of Artificial Intelligence PCBA: A New Era in Electronics

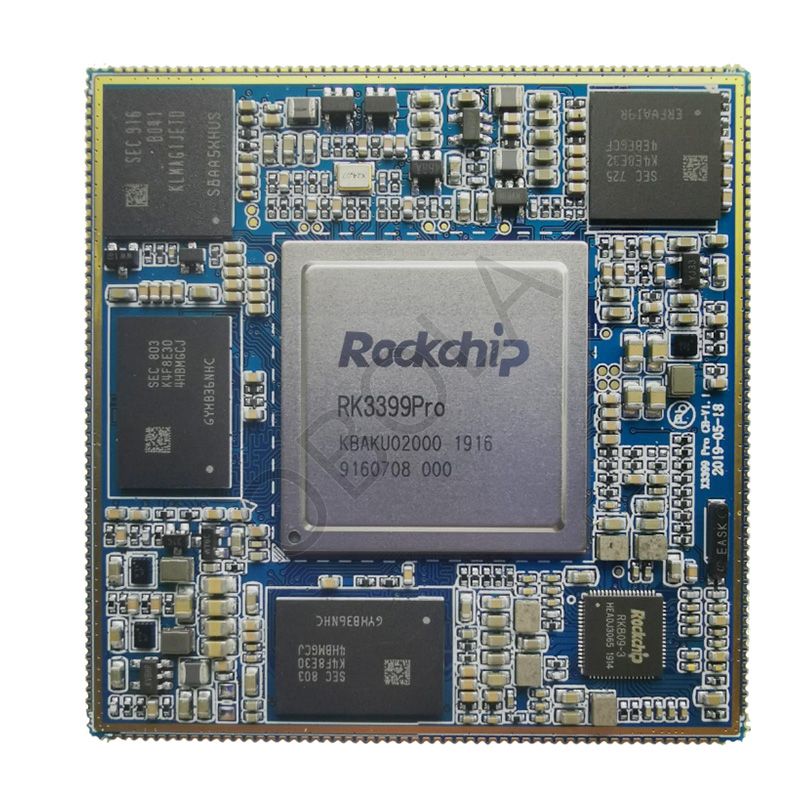

Understanding ARM SOM Core Boards: A Brief Overview

Factors to Consider When Selecting Power Resistors

Advantages and Applications of Mini Compact Substations

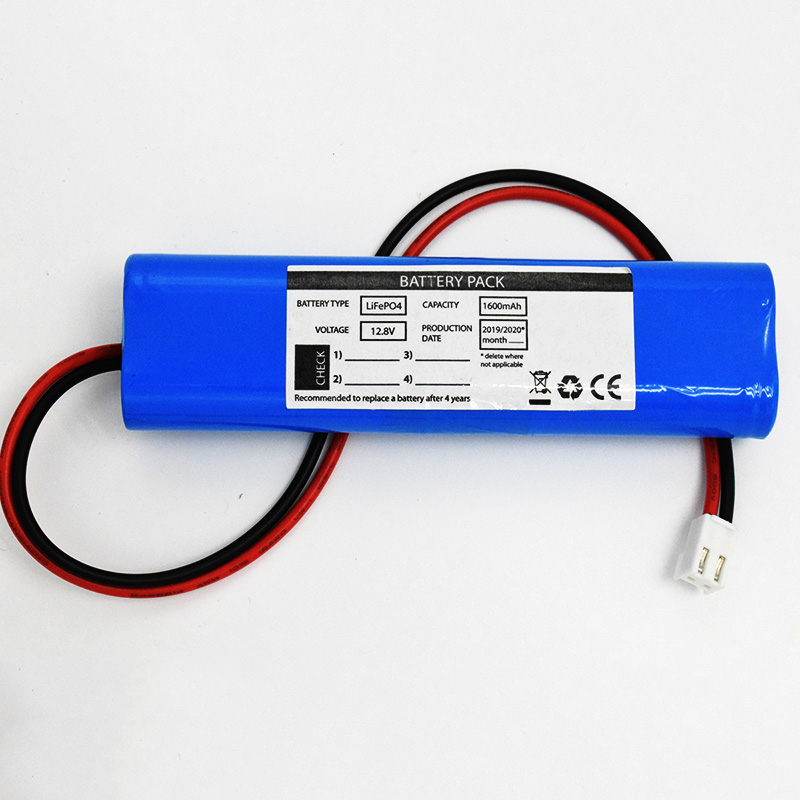

Understanding LiFePO4 Batteries: A Powerful and Sustainable Energy Solution

Flexible Metal Conduit: Versatile Conduit Solutions

PM OLED Display vs. AM OLED Display: Unveiling the Ultimate Visual Technology Showdown

Worker Safety and Ergonomics

The lithium battery module assembly line prioritizes worker safety and ergonomics. Automated processes reduce the need for manual handling of heavy battery components, minimizing the risk of workplace injuries. Safety measures, such as interlocking systems and protective barriers, are integrated into the assembly line to prevent accidents and ensure a safe working environment. Ergonomic considerations are taken into account in the design of workstations and equipment to promote worker comfort and reduce physical strain during the assembly process.

Sustainability and Environmental Impact

The lithium battery module assembly line embraces sustainability principles and minimizes its environmental impact. Efforts are made to optimize energy efficiency by implementing energy-saving technologies and systems, such as regenerative braking and smart power management. Waste reduction strategies are incorporated, including recycling and proper disposal of battery components. Additionally, the assembly line may utilize renewable energy sources, such as solar or wind power, to reduce reliance on fossil fuels and minimize carbon emissions.

Research and Development Innovation

The Lithium battery module automatic assembly line serves as a hub for research and development (R&D) innovation in battery technologies. Manufacturers continuously explore new materials, production techniques, and design improvements to enhance battery performance, energy density, and cycle life. The assembly line provides a platform for R&D teams to test and implement innovative ideas, paving the way for advancements in lithium battery technology and driving the future of energy storage.

Conclusion

The lithium battery module assembly line plays a crucial role in the efficient and reliable production of high-quality battery modules. Through its automated manufacturing processes, quality control measures, flexibility, and scalability, the assembly line ensures the consistent production of lithium-ion battery modules to meet the growing demands of various industries. By prioritizing worker safety, sustainability, and R&D innovation, the assembly line contributes to the advancement of battery technologies, shaping the future of energy storage and sustainable power solutions.

Additional reading:Liquid Tight Flexible Metal Conduit: Versatile, Durable, and Secure

Comparing LiFePo4 Battery Packs to Traditional Lithium-ion Batteries

Where is Waterproof Flexible Metal Conduit Typically Used?

What happens when a PTC is heated?

Are Compact Substations the Ideal Choice for Large-Scale Power Distribution Projects?

The Ultimate Guide to LCD Modules: Unleashing Innovation and Efficiency

Advantages of Vertiv Liebert UPS Rectifier Cabinets

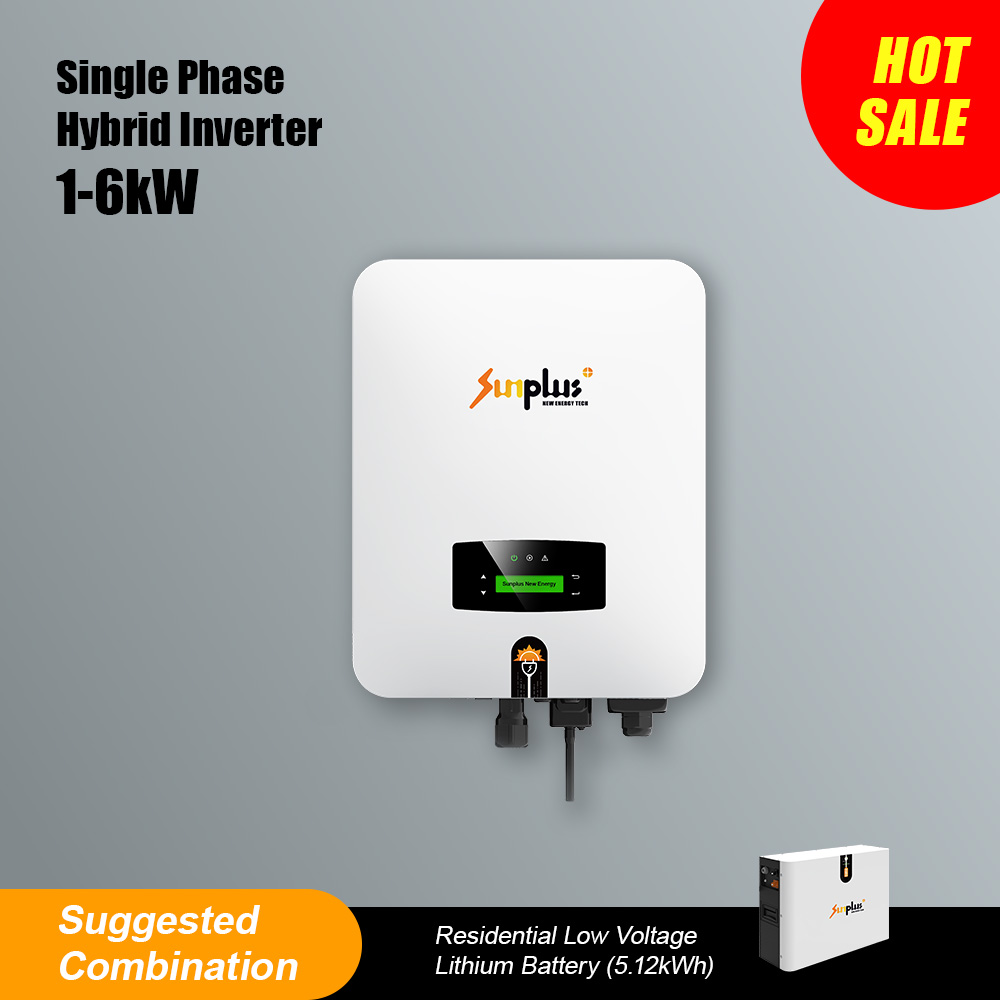

Previous: Empowering Homes: Exploring the Potential of Household Energy Storage

Next: What Is The Difference Between PTC And A Normal Heater?

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0