Unlocking Precision and Efficiency: How Fiber Laser Cutting Machines Work

Introduction

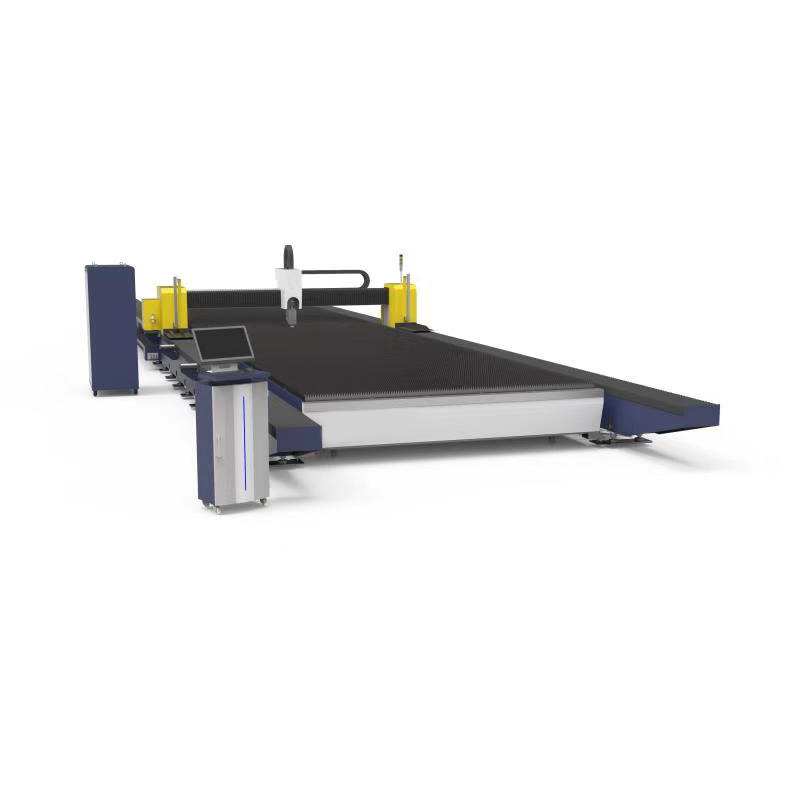

Fiber laser cutting machines have revolutionized the manufacturing industry with their ability to cut through various materials with unparalleled precision and efficiency. These cutting-edge machines utilize advanced fiber laser technology to deliver precise and clean cuts, making them indispensable in industries such as automotive, aerospace, electronics, and more. In this article, we will explore the working principles of fiber laser cutting machines, shedding light on the processes that enable their remarkable performance and the advantages they offer over traditional cutting methods.

Understanding Fiber Laser Cutting

Fiber laser cutting is a process that involves using a high-powered fiber laser beam to melt, vaporize, or burn through materials, allowing for precise and accurate cuts. The key components of a fiber laser cutting machine include the laser source, focusing optics, cutting head, motion system, and control software. Let's delve into the working principles of each component:

Laser Source

At the heart of a fiber laser cutting machine is the laser source, which generates a high-intensity laser beam. Fiber lasers employ a doped fiber optic cable as the laser medium, offering exceptional efficiency and power output. The laser beam emitted by the source has a small diameter and high energy density, making it ideal for achieving precise cuts with minimal heat-affected zones.

Focusing Optics

The laser beam generated by the source is directed through a series of focusing optics, including lenses and mirrors. These optics are responsible for shaping and focusing the laser beam into a concentrated and powerful beam. The focused laser beam is then directed towards the material being cut, ensuring maximum energy delivery at the cutting point.

Cutting Head

The cutting head is the component that contains the nozzle through which the laser beam is delivered to the material. It also includes additional optics to further refine the laser beam and control its parameters. The cutting head is designed to move along the material's surface, guiding the laser beam to create precise cuts according to the programmed design.

Motion System

The motion system of a fiber laser cutting machine consists of a combination of motors, drive systems, and precision guides. This system enables precise movement and positioning of the cutting head along the material being cut. The motion system ensures that the laser beam follows the programmed cutting path with high accuracy and repeatability.

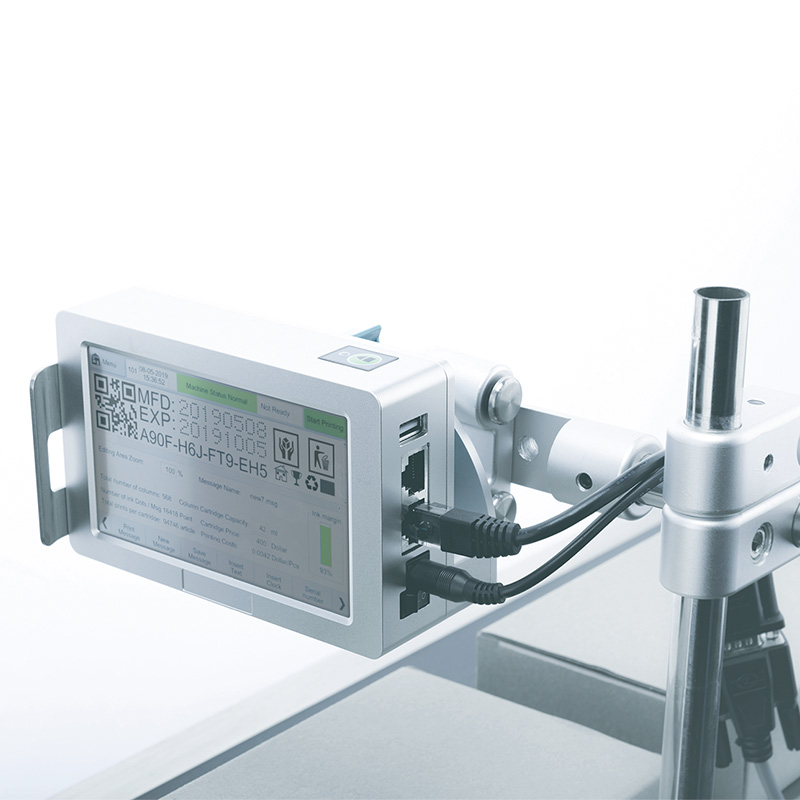

Control Software

To operate a fiber laser cutting machine, specialized control software is used. This software allows operators to import design files, create cutting paths, and control various machine parameters. The control software provides a user-friendly interface for programming and monitoring the cutting process, ensuring efficient and precise execution.

The Working Process

Now that we understand the key components of a fiber laser cutting machine, let's explore the working process that enables its exceptional cutting capabilities:

Design Preparation: The desired design or pattern is created using computer-aided design (CAD) software. The design file is then imported into the control software of the laser cutting machine.

Additional reading:10 Surprising Uses for Putrescible Organic Matter

Revolutionize Flour Packaging in Nigeria with Manual Machine

Revolutionizing Energy Storage: Pouch Lithium Batteries Reimagined?

Revolutionizing Metal Finishing: Acid Zinc Plating Machine – A Game Changer?

Top Trends in Auto Carton Sealing Machines

SMT AGV Equipment: Revolutionizing Manufacturing Processes

Power and Performance: Exploring the Functions and Benefits of Diesel Forklifts

Material Preparation: The material to be cut is prepared and positioned on the cutting bed of the machine. Proper fixation and alignment are crucial to ensure accurate cutting.

Machine Setup: The cutting parameters, such as laser power, cutting speed, and focal length, are set according to the material type and thickness. The cutting path and sequence are programmed into the control software.

Laser Beam Generation: The fiber laser source generates a high-intensity laser beam, which is then guided through the focusing optics to create a concentrated and precise beam.

Cutting Process: The cutting head moves along the material's surface, following the programmed cutting path. The laser beam is directed onto the material, melting or vaporizing it along the cutting line. The motion system ensures precise movement and positioning of the cutting head, resulting in accurate cuts.

Process Monitoring: Throughout the cutting process, sensors and monitoring systems ensure that the parameters are maintained within the specified range. Real-time feedback allows for adjustments and optimizations if necessary.

Completion and Finishing: Once the cutting process is complete, the cut parts are separated from the remaining material. Additional finishing processes, such as deburring or surface treatment, may be performed to achieve the desired final product.

Advantages of Fiber Laser Cutting Machines

Fiber laser cutting machines offer numerous advantages over traditional cutting methods, making them a preferred choice for many industries. Some key advantages include:

Precision and Accuracy: Fiber laser cutting machines deliver exceptional cutting precision, allowing for intricate and complex designs with tight tolerances. The focused laser beam ensures clean and precise cuts, minimizing the need for secondary processing.

Speed and Efficiency: The high power and cutting speed of fiber laser cutting machines enable fast production cycles and increased productivity. These machines can handle a wide range of materials and thicknesses, reducing production time and costs.

Versatility: Fiber laser cutting machines are capable of cutting various materials, including metals (such as steel, aluminum, and copper), as well as non-metallic materials like acrylic and wood. This versatility allows for a wide range of applications across different industries.

Minimal Heat-Affected Zones: The concentrated laser beam of fiber lasers generates minimal heat-affected zones during the cutting process. This reduces material distortion, warping, and the need for additional post-cutting treatments.

Cost-Effectiveness: Fiber laser cutting machines offer long-term cost savings through reduced material waste, increased efficiency, and lower energy consumption. The precise cuts minimize material scrap, resulting in optimized material utilization.

Conclusion

Fiber laser cutting machines have transformed the manufacturing industry, enabling precise, efficient, and versatile cutting of various materials. By harnessing the power of fiber laser technology, these machines offer unrivaled precision, speed, and cost-effectiveness.

Understanding the working principles of fiber laser cutting machines provides insight into their remarkable capabilities and advantages over traditional cutting methods. As industries continue to evolve and demand higher quality and efficiency, Cylion fiber laser cutting machines will undoubtedly play a vital role in shaping the future of manufacturing and fabrication.

What Is a Butterfly Valve Vs a Globe Valve?

Exploring the Advantages of GFS Tanks with FRP Roof in Industrial Storage

Unlocking Efficiency and Precision with Handheld Fiber Laser Welding Machines

Electric Wheel Loader Applications

The Laser Cutter Revolution: Transforming Design and Manufacturing

Components of a Lithium Battery Module Assembly Line

The Advancements in PV Solar Panel Production Line: A Comprehensive Overview

Previous: A Comprehensive Guide to Maize Flour Milling Plants: Design, Operation, and Maintenance

Next: Introduction to Facing and Centering Machines: A Comprehensive Overview

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0