What is the process of valve grinding?

Valve grinding is a process used to ensure that the valves of an engine are properly seated within their valve seats. Over time, the valve seats and valves themselves can become worn or damaged, which can lead to a loss of compression and engine power. The valve grinding process involves using a valve grinding machine to grind the valves to ensure they fit properly within their seats. In this article, we will explore the process of valve grinding.

The first step in the valve grinding process is to remove the valve from the engine. This is typically done by first removing the valve cover and then removing the valve from the cylinder head. Once the valve is removed, it is important to inspect it for any signs of wear or damage. If the valve is found to be worn or damaged, it will need to be replaced.

The next step in the valve grinding process is to clean the valve and the valve seat. This is typically done using a solvent or a parts washer to remove any debris or carbon buildup that may have accumulated on the valve and valve seat. It is important to ensure that the valve and valve seat are completely clean before proceeding with the grinding process.

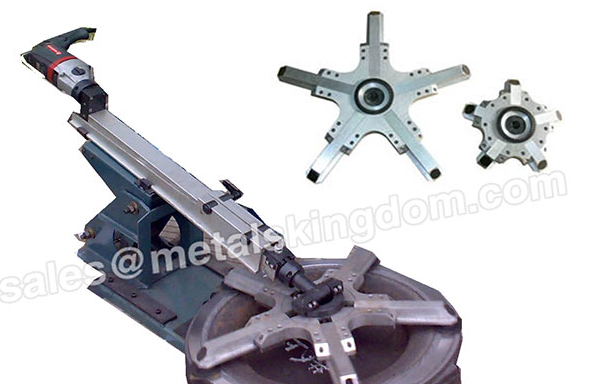

Once the valve and valve seat are clean, the valve is mounted in a valve grinding machine. The machine typically consists of a rotating grinding wheel that is used to grind the valve and a chuck that holds the valve in place during the grinding process.

The grinding wheel used in the valve grinding machine is typically made of a hard material, such as a ceramic or diamond abrasive, that can grind through the hardened steel of the valve and the valve seat. The grinding wheel is dressed to ensure that it grinds the valve evenly and does not leave any high or low spots on the valve.

Additional reading:SMT AGV Equipment: Revolutionizing Manufacturing Processes

Power and Performance: Exploring the Functions and Benefits of Diesel Forklifts

What Is a Butterfly Valve Vs a Globe Valve?

Exploring the Advantages of GFS Tanks with FRP Roof in Industrial Storage

Unlocking Efficiency and Precision with Handheld Fiber Laser Welding Machines

Electric Wheel Loader Applications

The Laser Cutter Revolution: Transforming Design and Manufacturing

The valve grinding process begins by bringing the grinding wheel into contact with the valve. The machine is then turned on and the valve is rotated by the machine while the grinding wheel grinds away the hardened steel of the valve and valve seat. This helps to ensure that the valve is ground evenly and is properly seated within its valve seat.

During the grinding process, it is important to ensure that the valve is rotated by the machine at the correct speed and pressure. This helps to ensure that the valve is ground evenly and that there are no high or low spots on the valve that could cause it to leak.

Once the valve has been ground to the correct size and shape, it is removed from the valve grinding machine and cleaned to remove any debris or grinding residue. The valve is then reinstalled into the engine and the engine is started to ensure that it is running properly.

In conclusion, valve grinding is an important process used to ensure that the valves of an engine are properly seated within their valve seats. The process involves using a valve grinding machine to grind the valves to ensure they fit properly within their seats. The valve grinding process requires careful attention to detail to ensure that the valve is ground evenly and properly. If you are an automotive mechanic, it is important to understand the valve grinding process and to invest in a safety valve grinding machine to ensure that you can provide the best service to your customers and keep their engines running smoothly.

Components of a Lithium Battery Module Assembly Line

The Advancements in PV Solar Panel Production Line: A Comprehensive Overview

Applications of Ribbon Mixers

The Development Direction of Heat Treatment

Portable Ultrasound Machine Reviews and Recommendations

Operation Steps of Vertical Pressure Steam Sterilizer

Advantages of Thermal Inkjet Printer

Previous: Multi-Stage Hydraulic Cylinder: Advancing Power and Precision in Industrial Applications

Next: None

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0