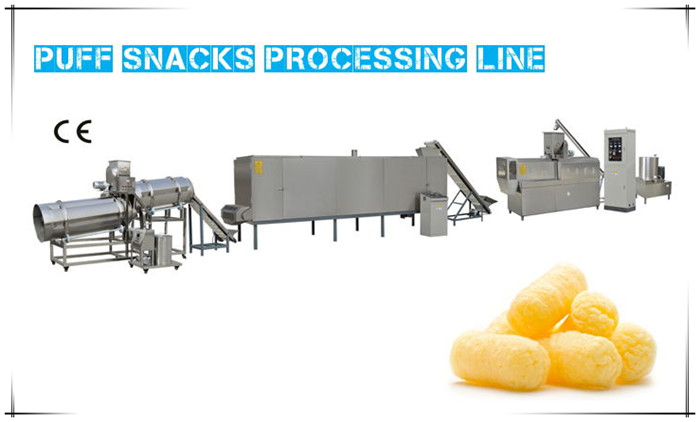

How Does the Puff Snacks Extruding Machine Work?

The Puff Snacks Extruding Machine is a versatile piece of equipment used in the food processing industry, particularly in the production of extruded puff snacks. This advanced machine operates on the principle of extrusion, a process in which a mixture of ingredients is forced through a die to obtain a desired shape and texture. The Puff Snacks Extruding Machine can be tailored to produce a wide array of puff snacks, such as cheese balls, corn puffs, rice puffs, and more.

How Does the Puff Snacks Extruding Machine Work?

The operation of the Puff Snacks Extruding Machine involves several crucial steps, each contributing to the final product's quality and consistency.

1. Ingredient Mixing

The process begins with the precise mixing of raw materials, including grains, flours, starches, flavors, and additives. This mixture forms the base of the puff snacks and determines their taste and texture.

2. Extrusion

The mixed ingredients are then fed into the extruder chamber, where they undergo intense pressure and heat. The combination of pressure and heat causes the mixture to expand rapidly, creating the characteristic puffed texture.

3. Die Design

The die, a critical component of the Puff Snacks Extruding Machine, shapes the extruded material into the desired snack form. The die's design determines the snack's size, shape, and texture, making it a crucial element in the production process.

4. Cutting and Shaping

As the extruded material emerges from the die, it is cut and shaped into individual snacks. The cutting process ensures uniformity in size and appearance, contributing to the overall appeal of the final product.

5. Flavoring and Seasoning

Once the puff snacks are formed, they undergo flavoring and seasoning processes to add distinct tastes and enhance their overall palatability. This step allows for a wide range of flavor options to cater to diverse consumer preferences.

6. Drying and Cooling

The freshly extruded and flavored puff snacks are then dried and cooled to achieve the desired texture and remove excess moisture. Proper drying and cooling play a crucial role in maintaining the snacks' crispness and shelf life.

Advantages of the Puff Snacks Extruding Machine

1. High Efficiency

The Puff Snacks Extruder Machine boasts high production efficiency, capable of manufacturing large quantities of puff snacks in a relatively short period. This efficiency helps meet market demands and reduces production lead times.

2. Versatility

With the ability to produce various snack shapes and flavors, the Puff Snacks Extruding Machine offers remarkable versatility. Manufacturers can easily adapt to changing consumer preferences and introduce new snack varieties.

Additional reading:Can Electronic Components Plating Machines Go Green?

Revolutionizing Packaging Industry: Heat Shrink Innovation?

10 Surprising Uses for Putrescible Organic Matter

Revolutionize Flour Packaging in Nigeria with Manual Machine

Revolutionizing Energy Storage: Pouch Lithium Batteries Reimagined?

Revolutionizing Metal Finishing: Acid Zinc Plating Machine – A Game Changer?

Top Trends in Auto Carton Sealing Machines

3. Consistency

The automated nature of the machine ensures consistent product quality, size, and texture across batches. This consistency is crucial for building consumer trust and loyalty.

4. Cost-effectiveness

By streamlining the snack production process and reducing manual labor requirements, the Puff Snacks Extruding Machine proves to be a cost-effective solution for snack manufacturers.

5. Enhanced Food Safety

Modern Puff Snacks Extruding Machines are designed with food safety in mind. They incorporate hygienic features that comply with stringent food industry standards, ensuring the production of safe and contamination-free snacks.

Applications of the Puff Snacks Extruding Machine

The Puff Extrusion Line finds applications in a wide range of settings, catering to diverse snack manufacturing needs.

1. Food Processing Industries

Food processing industries, particularly those involved in snack production, benefit immensely from the efficiency and versatility of the Puff Snacks Extruding Machine.

2. Snack Manufacturing Companies

Snack manufacturing companies, both large-scale and small-scale, can leverage the capabilities of the Puff Snacks Extruding Machine to expand their product lines and meet market demands.

3. Catering and Hospitality

The Puff Snacks Extruding Machine also caters to the catering and hospitality industries, providing them with the means to serve delicious and freshly made puff snacks to their customers.

4. Retail Snack Brands

Retail snack brands can utilize the Puff Snacks Extruding Machine to produce their signature snacks, ensuring consistent quality across all their products.

Conclusion

The Puff Snacks Extruding Machine has ushered in a new era of efficiency and innovation in the snack manufacturing industry. Its ability to produce a wide range of puff snacks with consistent quality and texture makes it an indispensable asset for snack producers across the globe.

At Dragons Machine, we recognize the significance of this revolutionary technology and are committed to providing cutting-edge Puff Snacks Extruding Machines that cater to the diverse needs of the food processing industry. Embrace the future of snack production with our state-of-the-art machines and elevate your business to new heights of success.

Additional reading:SMT AGV Equipment: Revolutionizing Manufacturing Processes

Power and Performance: Exploring the Functions and Benefits of Diesel Forklifts

What Is a Butterfly Valve Vs a Globe Valve?

Exploring the Advantages of GFS Tanks with FRP Roof in Industrial Storage

Unlocking Efficiency and Precision with Handheld Fiber Laser Welding Machines

Electric Wheel Loader Applications

The Laser Cutter Revolution: Transforming Design and Manufacturing

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0