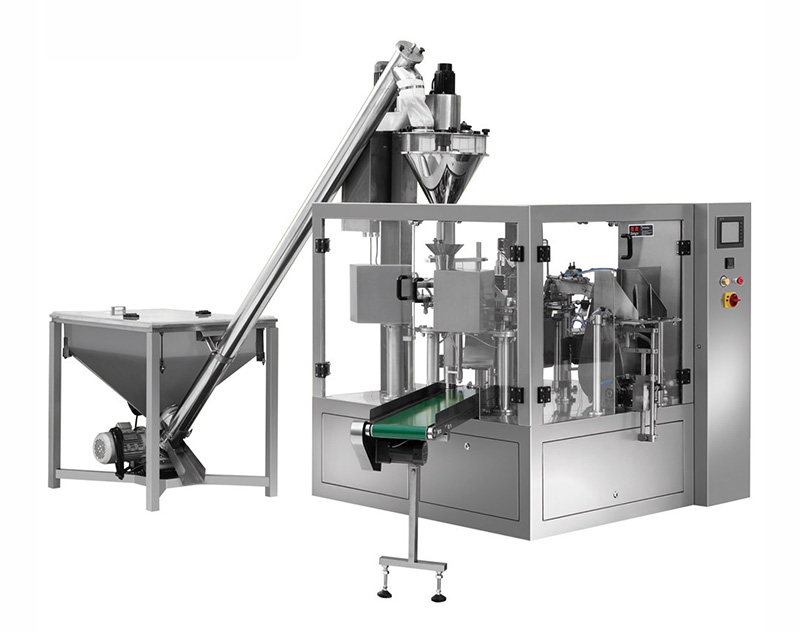

What is a pouch packaging machine used for?

A pouch packaging machine is a versatile and efficient device designed to package various products in flexible pouches or sachets. These machines are widely used in different industries to streamline the packaging process and ensure the products are securely and hygienically sealed. The main purpose of a pouch packaging machine is to package a wide range of products into convenient, portable, and attractive pouches. Here are some common uses of a pouch packaging machine:

1. Food Packaging: Pouch packaging machines are extensively used in the food industry to package items like snacks, candies, nuts, coffee, spices, sauces, and instant food products. The machines ensure the freshness and shelf life of the food products by providing airtight seals that prevent contamination and spoilage.

2. Pharmaceutical Packaging: In the pharmaceutical industry, pouch packaging machines are used to package single-dose medications, capsules, tablets, and other small medical products. The machines maintain the integrity of the medications, protecting them from external factors that could affect their efficacy.

3. Beverage Packaging: Pouch packaging machines are employed in the beverage industry to package liquid products like juices, energy drinks, yogurt, and liquid concentrates. The machines ensure that the beverages are securely sealed and leakage-proof for convenient consumption.

4. Personal Care and Cosmetics: Pouch packaging machines are utilized in the personal care and cosmetics industry to package products like shampoo, lotion, creams, gels, and other beauty products. The machines maintain the product's quality and prevent spillage during transportation and storage.

5. Cleaning and Household Products: stand up pouch packaging machine are used to package household cleaning products, such as liquid detergents, fabric softeners, and dishwashing liquids. The machines provide leak-proof seals that prevent spills and maintain product effectiveness.

6. Pet Food and Treats: In the pet food industry, pouch packaging machines are employed to package pet treats, snacks, and wet pet food. The machines ensure the products are hygienically sealed and easy to serve to pets.

7. Hardware and DIY Products: Pouch packaging machines are used to package small hardware items like screws, nails, bolts, and nuts. The machines create pouches that are convenient for customers and retailers to handle and store.

8. Agriculture and Seeds: Pouch packaging machines are utilized in the agriculture industry to package seeds, fertilizers, and agricultural chemicals. The machines ensure the products remain protected and uncontaminated.

Additional reading:How do you know if a Barrel Plating Machine is good to buy?

The Ultimate Buyer's Guide for Purchasing An Anodizing Machine

Advantages of Sheet Metal Laser Cutting Machine

What is the difference between induction motor and slip ring motor?

How many types of steam boilers are there?

What is the main purpose of Valve?

How does metal plating machines work?

Benefits of Pouch Packaging Machines:

Cost-Efficient: Pouch packaging machines are cost-effective, requiring less material compared to traditional packaging methods like boxes or bottles.

Versatile: Pouch packaging machines can handle a wide range of products, making them suitable for various industries.

Space-Saving: Pouches take up less storage space compared to rigid containers, optimizing inventory management.

Convenience: Pouches are lightweight, portable, and easy to open, providing convenience to consumers.

Customization: Pouch packaging machines offer options for customizing pouch size, shape, and design, allowing for branding and marketing opportunities.

In summary, Coretamp pouch packaging machines play a crucial role in efficiently packaging various products in flexible pouches. Their widespread use in different industries is a testament to their versatility, convenience, and cost-effectiveness in providing secure and attractive packaging solutions.

How to choose the right foam cutting machine?

What are the stages of battery manufacturing?

Advantages of Galvanizing Kettle for Purchase Stage?

What is the best strapping material?

How Ballistic Separator Recycling is Revolutionizing Waste Sorting

What is the disadvantage of BYD Blade battery?

Exploring the Most Popular Metal Plating Techniques

Previous: How Does the Puff Snacks Extruding Machine Work?

Next: What factors should I consider when choosing the unpowered beading machine for my crafting needs?

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0